IoT and Real-Time Monitoring Tools in Mining Industry

IoT platforms automatically collect and receive critical information from connected devices, allowing for real-time monitoring and analysis. This includes data on activities performed by sensors, gateways, and applications, as well as system health and status. For example, each time a device sends data to the cloud, the platform logs device ID, type of hardware and software being used (such as firmware version), and connectivity metrics. Additionally, the system tracks the source of data, the region where the devices operate, and specific actions taken (if applicable).

When you first deploy an IoT solution and when devices are connected to the platform, various Real-Time Data Points are captured, such as:

-

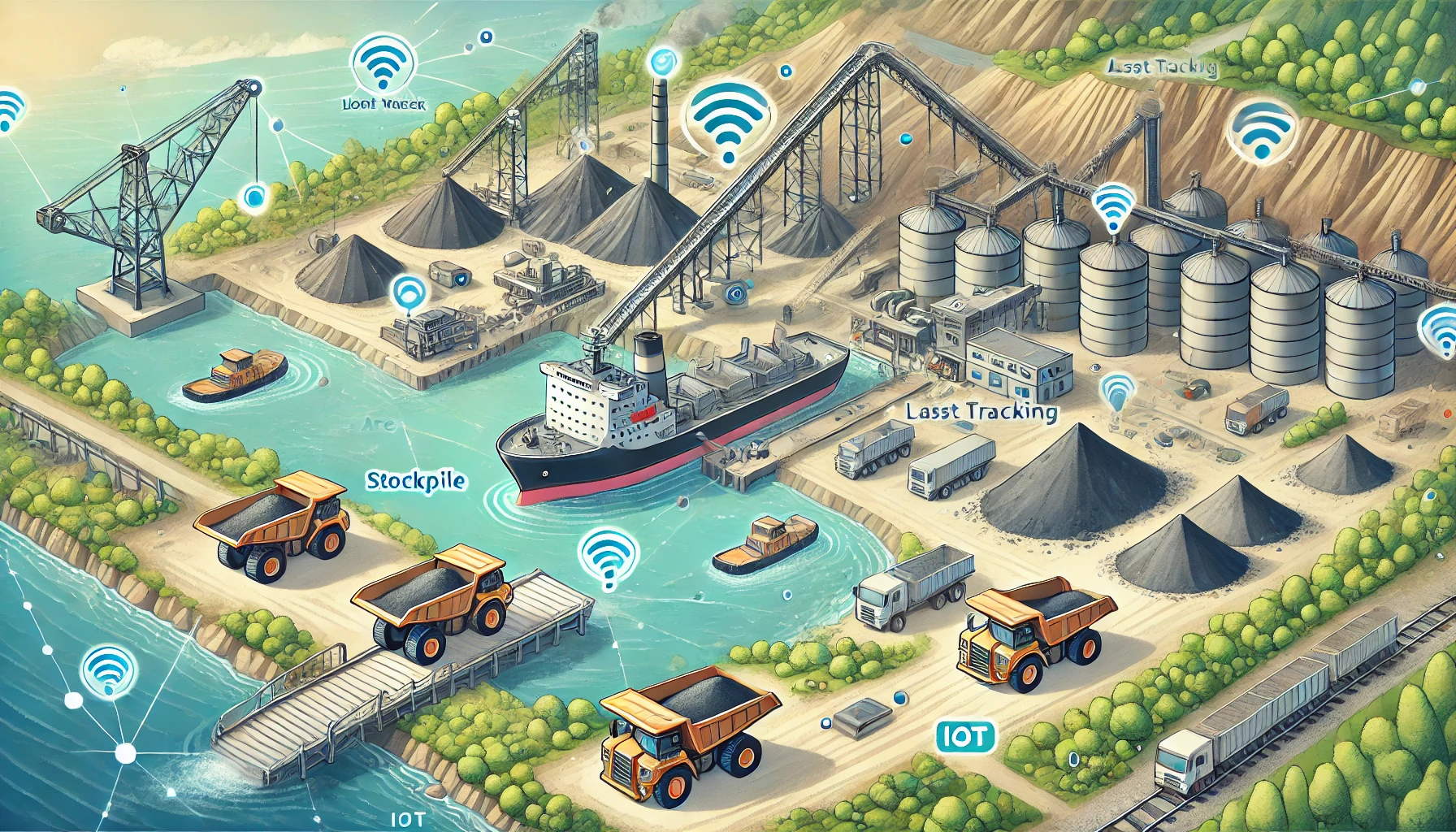

IoT technology in mining revolutionizes asset tracking for vehicles like dump trucks. Real-time tracking provides insights into performance, location, and condition, optimizing resource utilization and minimizing downtime.

-

IoT devices must align with network coverage, especially across vast mining sites, ensuring reliable data transmission for load weight, fuel usage, and route optimization.

-

IoT-enabled weight bridges capture real-time data on transported materials, allowing accurate flow tracking and preventing resource mismanagement.

-

Cloud replication and real-time alerts ensure no data loss and help operators quickly resolve discrepancies, maintaining smooth operations in mining environments.

Automating Weigh Bridge with IoT and Automatic Dump Truck Detection

IoT technology is revolutionizing the automation of weigh bridges in the mining industry, enabling real-time tracking and automatic detection of dump trucks as they approach and pass through the weigh station. This advanced system enhances the accuracy of weight measurements and eliminates manual interventions, streamlining operations and improving efficiency.

By integrating IoT sensors with the weigh bridge, the system automatically detects each dump truck's unique ID, records its weight, and logs the data instantly. This data is sent to a centralized monitoring platform, allowing operators to view weight records, track material flow, and manage stockpile levels in real time. The system can also alert operators if discrepancies in weight measurements or overloads occur.

With real-time data accessible via mobile applications, supervisors can monitor the performance of the weigh bridge and dump truck activities remotely. The automation of these processes ensures seamless operation, reduces the risk of human error, and improves overall productivity in the mining environment.